Digital Journey Companion

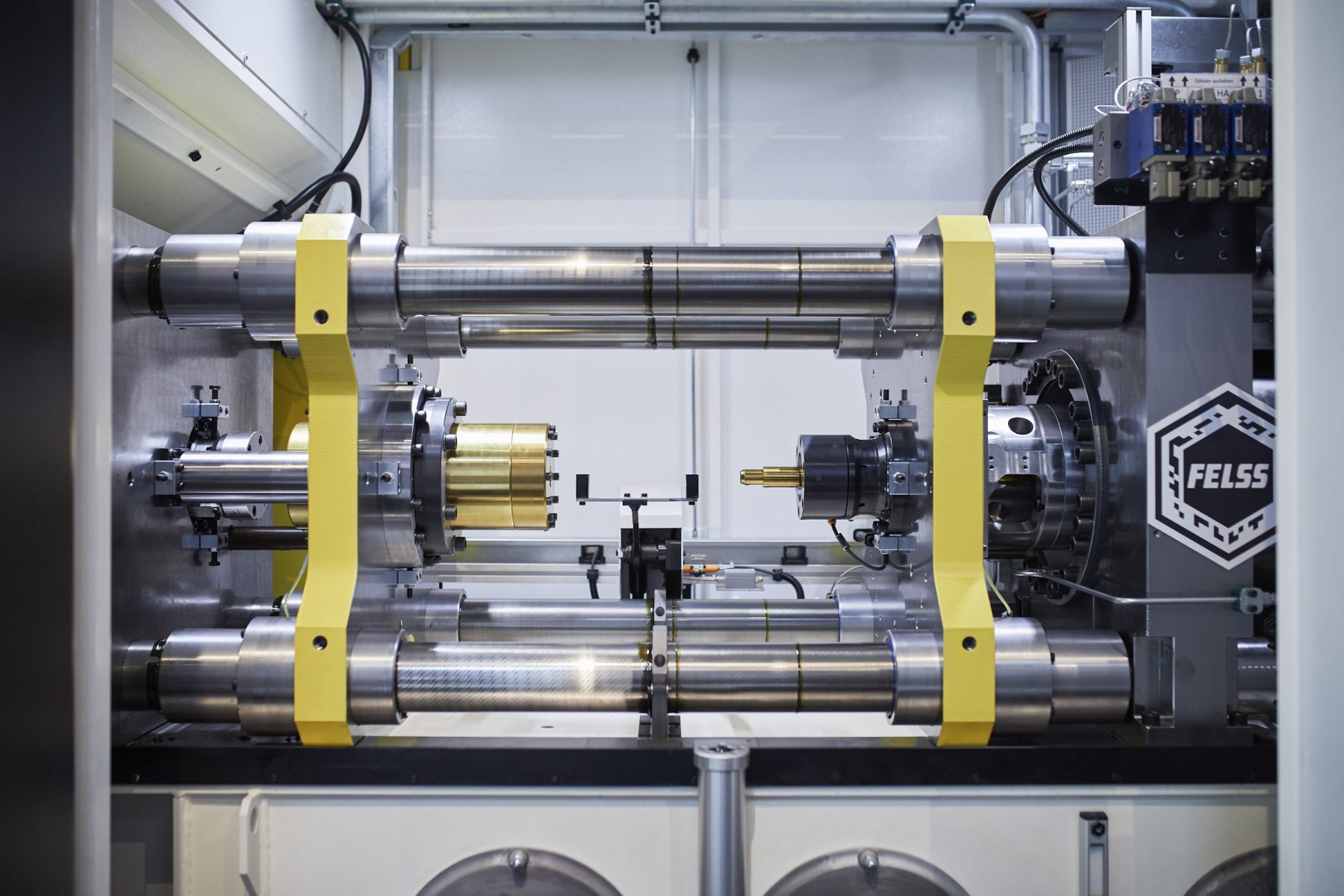

While undertaking this digital, future-oriented journey, Felss is able to benefit from Software Factory’s competence in a number of fields, who not only acts as a companion but also as a catalyst in tackling numerous Industry 4.0 issues facing the Felss Group. If you consider the areas Software Factory is engaged in as well as Felss’ aforementioned activities, then it is evident that the virtual product design of Tube+’s processes and products offers an array of new opportunities. On the product side, the AR application can be used to access the machine data, making the production processes inherently more transparent. In the instance with Felss, it can replace the traditional and often complex Graphic User Interfaces while also prepare the cloud connection for diagnosis and maintenance. On the development side, virtual models allow for more creativity and control over real products or parts. By superimposing the two models, colors, materials or entire components can be adapted and changed with minimal effort, whilst reproducing the real-size, three-dimensional objects in the actual environment. In terms of the logistics, Software Factory is able to show Felss how to recognize geometries that ensure the identification and consignment of parts, positively affecting the stock overall. In turn, the advantages in field-service and after-sales are also improved; technicians have on-site support that, for example, makes repair and its process flows clear. This connection to the ThingWorx platform could especially be used in component production, as it opens up untouched potential for its production and service world.