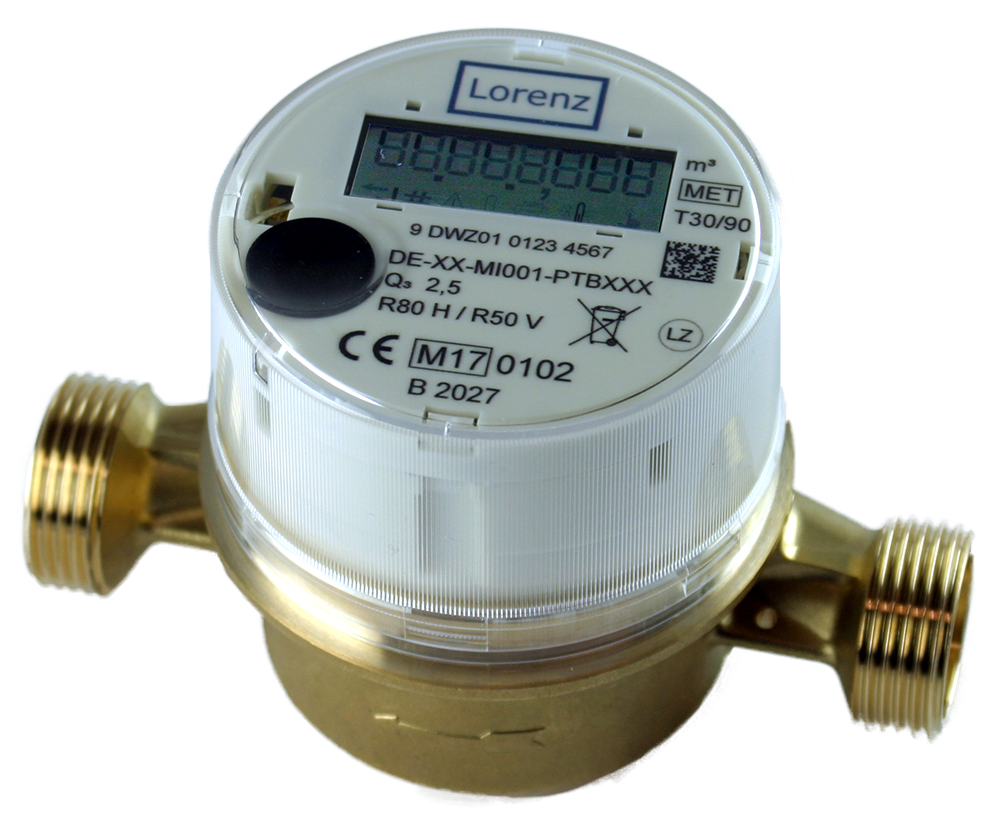

The goal of Lorenz, the leading German manufacturer of flow meters, was to implement a new, efficient production of intelligent wireless water meters that, in conjunction with networked water supply and billing, would improve Lorenz’s market opportunities. For the production of this new generation of water meters, a new production line was to be set up together with the sister company ITQ. Software Factory took over the necessary redevelopment of a fully integrated production control and production line system.

Lorenz wanted to network the data structures in the company so that not only the parameters in the production could be digitally controlled but also data security and encryption of the product data. The challenge was to integrate the different IT system worlds and to standardize the new forms of decentralized information provision from the planning to the shop floor level.

After the analysis phase at Lorenz, ITQ and Software Factory had been commissioned to develop the best possible combination of digitalization, shop floor management, production planning, material flow control and plant automation. The cornerstones of the system today are customized ERP and MES applications, including Scada functionality and augmented reality scenarios.